CAD Design Services

Introduction

Are you looking to bring your engineering concepts to life with unparalleled precision and efficiency? Look no further than our expert 3D CAD modeling and drafting services. By leveraging cutting-edge technology and years of industry experience, we offer a one-stop solution from concept to manufacturing that will revolutionize your design process.

Imagine reducing errors, improving accuracy, and significantly cutting costs – all while accelerating your time to market. That’s exactly what our services provide. Whether you need solid modeling, sheetmetal modeling, structural modeling, or intricate surfacing, our team has the expertise to deliver exceptional results.

But we don’t stop at modeling. Our comprehensive drafting services, including bid drawings, shop drawings, and manufacturing drawings, ensure that your designs are ready for production with minimal revisions. And for those looking to make a lasting impression, our photorealistic rendering capabilities will transform your products into stunning visual assets perfect for marketing campaigns.

By choosing our services, you’re not just getting a design – you’re investing in a partnership that values precision, efficiency, and innovation. Get more value for your money and stay ahead of the competition with our state-of-the-art 3D CAD modeling and drafting solutions.

Transform Your Ideas into Reality with Expert 3D CAD Modeling and Drafting

What we do:

- Provide comprehensive 3D CAD modeling and drafting services

- Create accurate and detailed engineering designs

- Develop photorealistic renderings for marketing purposes

Who we do it for:

- Engineers and designers

- Manufacturing companies

- Product development teams

- Marketing departments

What you get:

- Precise and error-free designs

- Faster time-to-market

- Cost-effective engineering solutions

- Enhanced product visualization for marketing

CAD Design Services we provide

Solid modeling is the foundation of modern product design. This powerful technique allows for the creation of precise, three-dimensional digital representations of physical objects. By utilizing solid modeling, you can visualize your product with incredible accuracy, test its functionality, and identify potential issues before moving to production. This not only saves time and resources but also ensures a higher quality end product. Whether you’re designing a simple component or a complex assembly, solid modeling provides the tools to bring your ideas to life with unparalleled precision.

Sheetmetal modeling is crucial for industries ranging from automotive to aerospace. This specialized form of 3D CAD modeling allows for the accurate representation of thin-walled parts, taking into account material properties, bend allowances, and manufacturing processes. By utilizing sheetmetal modeling, you can design parts that are not only functional but also optimized for production. This results in reduced material waste, lower manufacturing costs, and improved product quality. From simple brackets to complex enclosures, sheetmetal modeling ensures your designs are ready for efficient and cost-effective manufacturing.

Structural modeling is essential for ensuring the integrity and safety of buildings, bridges, and other large-scale constructions. This specialized service allows for the creation of detailed 3D models that accurately represent structural elements and their interactions. By employing structural modeling, you can get accurate cutlist of materal used and avoid any wastage. This leads to cost savings through material optimization and reduced construction time. From residential buildings to industrial complexes, structural modeling is your key to creating robust and efficient structures.

Surfacing is the art of creating complex, freeform shapes in 3D CAD. This advanced technique is crucial for designing aesthetically pleasing and aerodynamic products. Whether you’re working on automotive exteriors, consumer electronics, or industrial design, surfacing allows you to create smooth, continuous surfaces that are both beautiful and functional. By mastering surfacing, you can push the boundaries of design, creating products that stand out in the market. Moreover, high-quality surfaces lead to improved manufacturing processes, reducing the need for post-production finishing and ensuring a premium end product.

Bid drawings are your ticket to winning lucrative contracts. These detailed technical documents showcase your design intent and provide potential clients or contractors with the information they need to accurately estimate project costs. By investing in high-quality bid drawings, you increase your chances of securing projects and ensure that all parties have a clear understanding of the work involved. This leads to more accurate pricing, fewer misunderstandings, and a smoother project execution. From small projects to large-scale engineering endeavors, bid drawings are an essential tool for success in competitive tendering processes.

Shop drawings are the bridge between design and fabrication. These detailed technical documents provide fabricators and manufacturers with all the information they need to accurately produce your designs. By investing in comprehensive shop drawings, you minimize errors, reduce production time, and ensure that the final product matches your exact specifications. This not only saves money but also maintains the integrity of your design throughout the manufacturing process. From custom furniture to complex machinery, shop drawings are your guarantee of precision and quality in the fabrication process.

Manufacturing drawings are the blueprint for bringing your designs to life. These detailed technical documents provide manufacturers with all the necessary information to produce your product accurately and efficiently. By creating comprehensive manufacturing drawings, you ensure that every aspect of your design is clearly communicated, from dimensions and tolerances to material specifications and assembly instructions. This level of detail minimizes production errors, reduces waste, and accelerates the manufacturing process. Whether you’re producing a single prototype or preparing for mass production, manufacturing drawings are your key to consistent, high-quality results.

Photorealistic rendering is the art of transforming 3D CAD models into stunning, lifelike images. This powerful visualization tool allows you to showcase your products in their best light, even before they’re physically produced. By utilizing photorealistic rendering, you can create compelling marketing materials, impress potential investors, and gather valuable feedback on design aesthetics. This not only accelerates the design approval process but also gives you a competitive edge in the market. From architectural visualizations to product catalogs, photorealistic rendering brings your ideas to life with unparalleled realism and impact.

Frequently Asked Questions

3D CAD modeling is the process of creating three-dimensional digital representations of physical objects or designs using computer-aided design (CAD) software. It allows for precise visualization, testing, and modification of designs before physical production.

3D CAD modeling can significantly reduce design errors, improve product quality, accelerate time-to-market, and lower overall development costs. It also enables better communication of design intent and facilitates easier modifications.

Our services cater to a wide range of industries, including manufacturing, automotive, aerospace, consumer products, medical, and more. Any industry that requires precise design and engineering can benefit from our expertise.

We use industry-standard software such as SolidWorks. We can also work with specific version of software preferred by our clients.

Project duration varies depending on complexity and scope. Simple parts might take a few hours, while complex assemblies could take several weeks. We provide estimated time during our initial consultation.

Yes, we can convert 2D drawings or sketches into 3D CAD models. This process helps modernize legacy designs and allows for easier modifications and improvements.

Yes, we offer revision cycles as part of our service. We work closely with our clients to ensure the final model meets all specifications and requirements.

Simply reach out to us through our contact form or give us a call. We’ll schedule a consultation to discuss your project requirements and provide a custom quote.

Revolutionize Your Design Process

Don’t let outdated design processes hold you back – take the first step towards innovation and success. Contact us today to discover how our 3D CAD modeling can revolutionize your design process and give you a competitive edge in your industry.

FEA Analysis

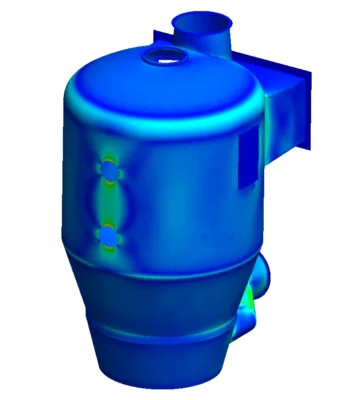

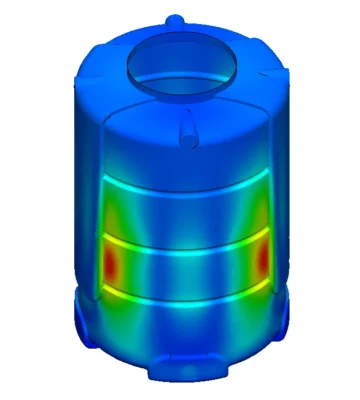

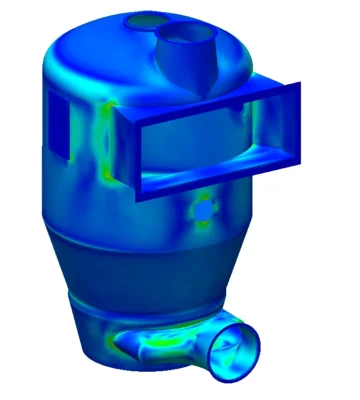

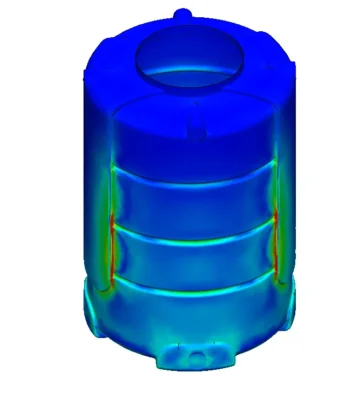

In the dynamic landscape of product design, structural integrity is paramount, and our FEA analysis services stand as the beacon for ensuring your designs not only meet but exceed performance expectations. At Pinnacle Steel Fabricators, we understand the critical role that FEA plays in the design and optimization of a product. Our team of experienced engineers utilizes advanced FEA software and methodologies to provide in-depth analysis, simulation, and validation of your designs, ensuring they withstand real-world conditions and performance criteria. Our FEA analysis services begin with a comprehensive understanding of your project requirements, design goals, and performance expectations. Whether you’re validating the structural integrity of a complex mechanical component or assessing the durability of a structure, our team collaborates closely with you to tailor our analysis approach accordingly.

Why Choose Pinnacle Steel Fabricators for FEA?

We leverage the power of FEA to simulate and analyse the behaviour of structures under various loading conditions, environmental factors, and material properties. This allows us to identify potential weaknesses, optimize designs for performance and efficiency, and ultimately deliver solutions that are not just functional but excel in reliability and durability.

Each analysis is conducted with meticulous attention to detail, adhering to industry standards and best practices. Our commitment to precision ensures that the insights derived from the FEA process are accurate, actionable, and invaluable in guiding design improvements.

What sets Pinnacle Steel Fabricators apart is our commitment to staying at the forefront of engineering technology. We invest in continuous training and advancements in FEA methodologies, ensuring that our clients benefit from the latest tools and insights in structural analysis.

Choose Pinnacle Steel Fabricators for FEA analysis services that go beyond traditional boundaries. Elevate your designs with our expertise, ensuring that your products not only meet regulatory requirements but also surpass expectations in terms of reliability, safety, and performance. With Pinnacle Steel Fabricators, your engineering challenges become opportunities for innovation and excellence.